Use coupon code MOISTURIZER with your purchase of $40 or more for a free†

Blemish Clear MoisturizerNOW's World Class Labs

How do you measure quality?

When it comes to guaranteeing the unsurpassed quality of NOW’s 1,500+ natural products, testing and scientific analysis make the difference. Our dedication to comprehensive testing in the most extensive in-house labs in the industry sets us apart from other natural products manufacturers. Did you know that NOW performs more than 31,000 analyses and tests each month? We test incoming raw materials and ingredients, in-process ingredients, and finished goods to ensure our products meet or exceed CGMP standards established by the U.S. Food and Drug Administration (FDA) in our ISO-certified, world-class labs.

In-House Laboratories

NOW is one of the few manufacturers in the natural products industry to own and operate its own in-house laboratories. In fact, we don’t just have one, we have several:

-

Sample Preparation Lab – Analytical chemists employ a wide range of extraction procedures and equipment to separate compounds of interest from diverse sample matrices in preparation for subsequent analysis using a variety of analytical instruments.

-

Physical Testing Lab – Our physical testing laboratory serves as the hub for all of NOW’s physical attribute testing. Here, we meticulously analyze key ingredient attributes including weight, thickness, density, dissolution, and melting point, among others, to uphold the standards of identity and quality.

-

Analytical Testing Labs – In our analytical testing laboratories, we house some of the most advanced analytical instrumentation, which includes gas chromatography, high-performance liquid chromatography, and other sophisticated equipment. We employ a diverse range of analytical techniques and instruments to identify chemical constituents and to guarantee the absence of contaminants and adulterants in raw materials and finished products.

-

Research & Development Lab and Pilot Plant– We engage in the continual development and testing of new formulations and product concepts. Our ongoing objective is to identify novel combinations of complementary ingredients that can effectively contribute to the enhancement of overall health.

-

Microbiology Lab – Microbiological screening stands as a critical step in ensuring the safety and quality of our natural products, encompassing supplements and natural foods. Our meticulous testing program is specifically tailored to uphold the safety standards of all our products.

Additionally, NOW has a dedicated Method Development team that focuses on developing and validating in-house testing methods that are suitable for the materials being tested. The team is also involved in research projects that concentrate on new approaches for testing chemical constituents and contaminants.

See below for more info on the analytical instruments you’ll find in our labs.

Cutting-edge Analytical Instrumentation

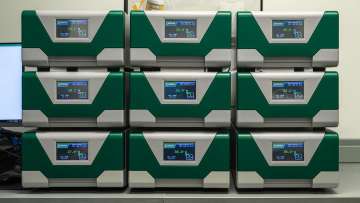

Soleris® Next Generation System

Rapid Microbiological System that has reproducible, rapid, and accurate detection of a variety of microorganisms across a spectrum of sample types. Measures microbial growth by monitoring changes in pH, CO2 Production, or fluorescence activity. NOW® owns 16 of these instruments.

RiboPrinter®

NOW® technicians utilize this powerful, cutting-edge tool to guarantee the identity, potency, and purity of the bacterial strains used in our probiotic products and to help identify potential bacterial contaminants before production.

Neogen® Molecular Detection System (MDS)

Rapid molecular detection system that uses isothermal DNA Amplification and Bioluminescence detection to identify a variety of pathogenic microorganisms in environmental samples, raw materials, and in-process samples. NOW® owns two of these instruments.

GENE-UP®

This machine is a real-time PCR-based system for detecting a variety of pathogenic microorganisms in environmental samples, raw materials, and in-process samples. NOW® owns three of these instruments.

High-Performance Liquid Chromatography (HPLC)

One of our most important and versatile instruments, HPLC is a cornerstone of our analytical capabilities. It allows our scientists to assess the purity and potency of various materials by separating and quantifying compounds in raw materials and finished product samples, ensuring the quality of our products. NOW® owns 23 of these instruments.

Ion Chromatography (IC)

Similar to HPLC but intended specifically for analysis of charged and highly polar compounds. Ion chromatography instrumentation is highly robust and is used for testing of sugars, sugar alcohols, amino acids, etc. NOW® owns two of these instruments.

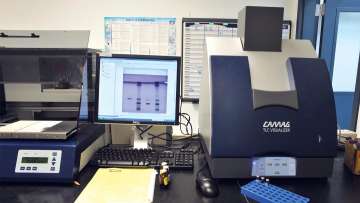

High-Performance Thin-Layer Chromatography (HPTLC)

With HPTLC, NOW® chemists can correctly identify botanical species and the composition of plant-derived powders and extracts. Our chemists also use HPTLC to differentiate between the expected sample composition and an adulterated sample.

Gas Chromatography (GC)

When NOW® chemists need to analyze EPA and DHA in oils, other compounds such as MSM, GC is the instrument they turn to. GC is also used to perform fatty acid profiling. We compare a specific fatty acid profile to an established profile database, allowing our chemists to detect if an oil is synthetic, adulterated, contaminated, or degraded. NOW® owns five of these instruments.

Inductively Coupled Plasma-Mass Spectrometry (ICP-MS)

ICP-MS is a highly sensitive analytical technique that allows our chemists to detect even trace amounts of elements in various substances, including heavy metals such as arsenic, cadmium, lead, and mercury. NOW® owns two of these instruments.

Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES)

Similar to the ICP-MS, but specifically designed to handle higher concentrations of minerals and used to quantitate the content of magnesium, calcium, zinc, etc. in raw materials and finished products.

Liquid Chromatography Quadrupole Time-of-Flight Mass Spectrometry (LC-QTOF-MS)

LC-QTOF-MS allows NOW® chemists to identify sample chemicals by detecting them based on their molecular weight. This instrument provides a high-precision accurate mass analysis for profiling, identifying, characterizing, and quantifying low molecular weight compounds.

Liquid Chromatography Orbitrap Mass Spectrometry (LC-Orbitrap-MS)

This machine is an extremely sensitive high–resolution accurate mass (HRAM) spectrometry instrument. It allows chemists to identify chemical compounds based on their molecular weight. The high-resolution feature of this instrument allows for unique workflows, such as untargeted analysis, which allows chemists to identify unexpected contaminants or adulterants in a sample. Many of our adulterant screens use HRAM technology.

Ultraviolet/Visible Spectroscopy (UV/Vis)

This specialized analytical technique helps NOW® staff determine the content of a liquid by analyzing its light absorption. Different compounds absorb different light colors, and this technique helps to confirm raw material identity and strength.

Gas Chromatography-Tandem Mass Spectrometry (GC-MS/MS)

A highly versatile analytical instrument for the analysis of volatile compounds, GC-MS/MS is used by NOW® chemists to perform multi-residue pesticide and residual solvent analyses. NOW® owns two of these instruments.

Gas Chromatography-Mass Spectrometry (GC-MS)

Similar to the GC-MS/MS, the GC-MS is an instrument for analyzing volatile compounds. At NOW®, it is used specifically to test the constituents of essential oils to confirm their identity and purity.

Gas Chromatography with Flame Ionization Detector and Headspace Sampler - Mass Spectrometry (GC/FID/HS-MS)

Similar to the GC-MS/MS, the GC/FID/HS-MS is specifically used to perform residual solvent analysis.

Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS)

Similar to GC-MS/MS, this analytical instrument is used to perform analysis of compounds at trace levels (micrograms or even picograms), such as pesticide residues, vitamin D3 or K2. NOW® owns two of these instruments.

Ion Chromatography/Mass Spectrometry (IC-MS/MS)

Similar to LC-MS/MS, this analytical instrument is also used for pesticide testing. IC/MS/MS is specifically utilized to analyze the common pesticide, glyphosate (i.e., Round-Up), and its metabolites at the parts per billion (ppb) level.

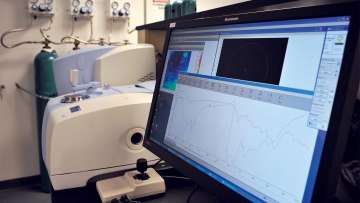

Infrared Spectroscopy (IR)

Another sensitive method for identifying raw materials, IR involves exposing a sample to energy to make the compounds’ chemical bonds vibrate. Vibrational patterns will vary depending on a raw material’s unique chemical composition, which a trained chemist uses to verify the material’s identity. NOW utilizes Fourier Transform infrared (FTIR) and Near-Infrared (NIR) spectroscopy. NOW® owns two of these instruments.

Enzyme-Linked Immunosorbent Assay (ELISA)

A very sensitive methodology for detecting allergens, this technique plays a significant function in our food safety program. Protein residues (antigens) from specific allergens are reacted with antibodies and analyzed using a plate reader.